Some of the key benefits of CNC machining include increased accuracy, reduced risk of human error and reduced manpower. Here are some of the advantages of CNC machining for your business. Let’s start with the safety aspect. CNC machines use preprogrammed computer software to control movement of machinery. They reduce the need for human labor and increase production speed. Moreover, CNC machining is more cost-effective than conventional machines.

Reduces risk of injury

Most health and safety accidents involving CNC machining occur because engineers bypass safety interlocks and work around them. Under time-pressure, risk-taking seems preferable to waiting for a safe solution. However, the right equipment and procedures can help streamline production and keep operators safe. For example, wearing ear defenders while CNC machining is not recommended, as this can impede workshop communication. Therefore, it is imperative to follow HSE safety procedures.

Increases accuracy

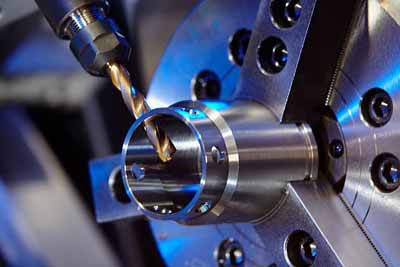

CNC Machining is a common practice that requires high levels of accuracy and precision. Even a very small amount of inaccuracy can cause defective products and put consumers’ safety at risk. This article describes a way to increase the accuracy of CNC machining processes. In this article, we look at a specific example and discuss the benefits of this method. You’ll find that CNC machining increases accuracy and efficiency.

Reduces risk of human error

CNC machines are designed to cut down on human error. Unlike hand-operated machines, CNCs can operate 24/7, with fewer breaks. They can also be monitored remotely for maintenance purposes, which reduces the risk of machine breakdowns. They are also highly efficient, enabling manufacturers to produce many customer orders in a shorter time. And because they are so accurate, CNCs also cut down on energy consumption.

Reduces manpower

A major benefit of CNC Machining is its cost effectiveness. Typically, the cost of CNC machines is a fraction of human labor, as each machine can be operated by just one operator. In addition, these machines can be left unattended, meaning operators can focus on other tasks while the machine is in a state of rest. Further, by diversifying the scope of tasks, manufacturers can increase the efficiency of their workforce. Though the initial purchase of CNC machines is expensive, the payback period is only a few years.

Allows for constant and continuous production

CNC machining provides a multitude of advantages over traditional manufacturing methods, including the ability to automate processes. Human operators are limited by their ability to work for eight hours a day, making it difficult for them to maintain a high standard of accuracy. Continuous production also reduces fixed costs per unit, as CNC machines can perform multiple operations with a single machine. Here are three benefits of CNC machining. These advantages can make this process a cost-effective option for manufacturing complex parts.